Clean Water and Power Technologies Can Be Combined to Recycle Carbon Dioxide (CO2)

Krebs & Sisler L.P. is licensing it's clean water and power technologies developed over many years of research. All of the combustion exhaust gas CO2 can be economically recycled. See the Technology Background.

The O2/CO2 Combustion Condensing Boiler

O2/CO2 combustion is detailed in United States Patent No. 6,907,845 granted June 21, 2005(pdf version). China Patent No. ZL20038010 was granted August 19, 2009 and Japan Patent No. 4416661 was granted December 4, 2009. Our fuel combustion concept is based on a unique condensing boiler system adaptable to either closed Rankine cycle or combined cycle power units. Due to recent improvements, we now expect that power units scaled from 5 megawatts (MW) to at least 300 MW will operate with no harmful emissions at electric power production efficiencies of 50% to above 80% when optimized. This combustion technology is also adaptable to cement kiln operations with waste heat recovery for steam electric generation and with virtually 100% CO2 recovery and profitable use. The CO2 may be used to grow specific algae biomass which can be harvested and dried for fuel, for animal feed, or a human food supplement.

CO2 Water Purification

Our water purification process uses photosynthesis to grow species of algae which require CO2 and photocatalysis to destroy toxins. It is discussed on this website in Combining Municipal Services and CO2 Desalinization. More details were disclosed in a September 13, 2010 news release. A patent is pending. The expected high algae growth rate depends on the optimization of many factors including CO2 saturation, balanced nutrients, enclosed all-weather facilities with 24-hour LED lighting and sufficient time in a continuous hydroponic process.

CO2 Recycling

Carbon capture and

sequestration (CCS) is proposed to dispose of the large amounts of CO2 emitted by power plants. The costs of CCS, added to the price of

electric power production, will be very high. Recycling CO2 from O2/CO2

combustion electric power units should lower costs, particularly where water and power operations are combined and located near population centers. This arrangement will provide the large

amounts of free CO2 needed for either wastewater treatment or for salt water desalinization.

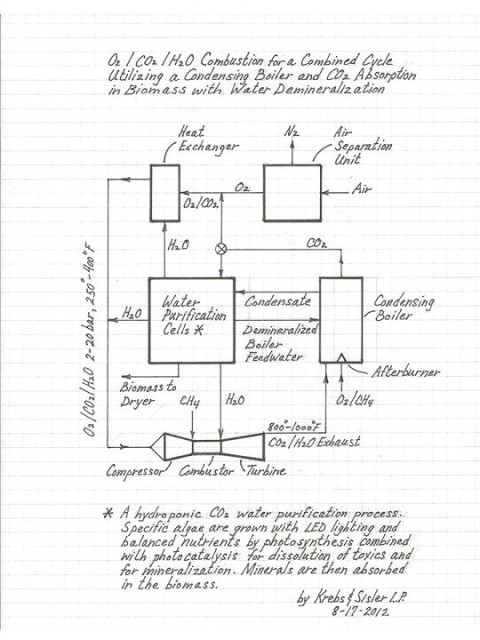

Combined Cycle O2/CO2/H20 Combustion

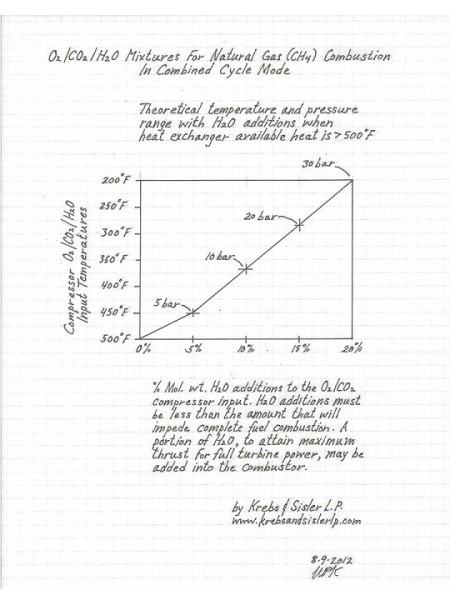

We are developing O2/CO2/H20 combustion for gas turbines. The method is combined with a condensing boiler. This combination increases power output and efficiency and facilitates the economical separation of all CO2 and condensate recovered from the boiler. Improvements to the power system include 1) recycling large amounts of waste heat otherwise discarded into the environment, 2) using byproduct CO2 to grow biomass and 3) demineralizing boiler condensate by the absorption of minerals in the growth of biomass. The combination of photosynthesis and photocatalysis enables a high rate of algae growth and wastewater demineralization.

The gas turbines of most manufacturers may be retrofitted to O2/CO2/H2O combustion combined cycle operation. A steady input of oxygen, carbon dioxide, and water or steam is ducted into the gas turbine compressor and combustor at an elevated temperature and pressure, replacing ambient air drawn into the compressor for the combustion medium otherwise used in air-fired natural gas-fueled combustion turbines. Significant savings result from reducing the parasitic shaft power charged to the compressor. This more than offsets the electric power cost of operating the air separation plant required to produce the oxygen for O2/CO2/H2O combustion. Steam electric power capacity may be increased several times by adding an oxygen-fired natural gas afterburner to the condensing boiler and adding steam turbine/generator capability.

Please direct inquiries to:

Krebs & Sisler Limited Partners

Telephone 1 (312) 236-9724

krebsandsislerlp@krebsandsislerlp.com

November, 2012